Course Search Results

Course Search Results

Course Name

Electrical and Mechanical Modules (BEng)Course Description

The Electrical and Mechanical Modules (BEng) of the Beng in Railway Engineering at Sheffield Hallam UniversityAudience

Only those enrolled via the University on the Applied Engineering ProgrammeDuration:

0 Day(s)Class size:

0

Course Name

Electrical and Mechanical Modules (BEng)Course Description

The Electrical and Mechanical Modules (BEng) of the Beng in Railway Engineering at Sheffield Hallam UniversityAudience

Only those enrolled via the University on the Applied Engineering ProgrammeDuration:

0 Day(s)Class size:

0Competence Name Awarded:

N/ACompetence Awarded:

N/ACourse Code:

BENGREPrerequisite Name:

N/APrerequisite Short Code:

N/ASkills Assessment Scheme Regime:

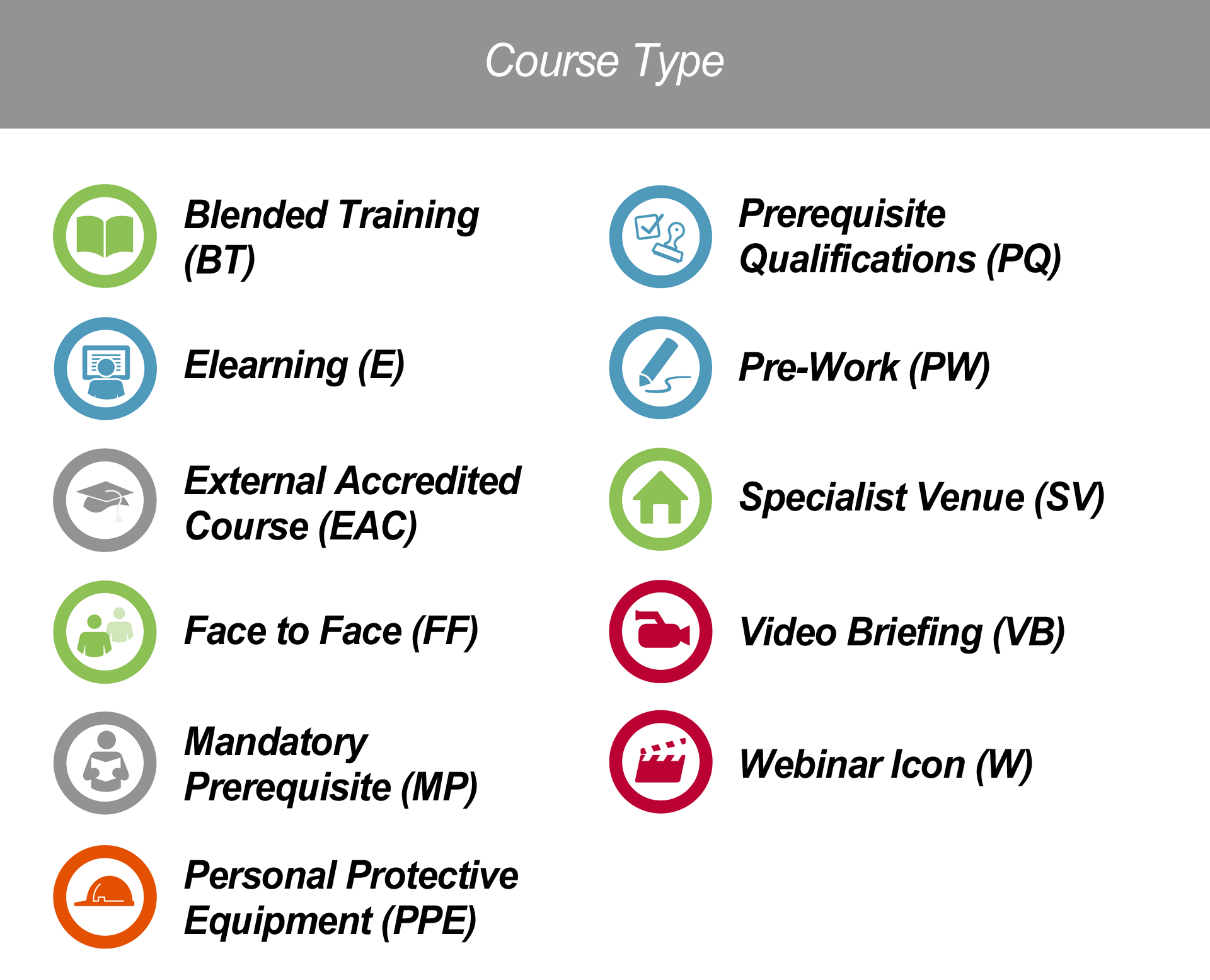

N/ACourse Type:

Course Name

Electrical and Mechanical Modules (Fd)Course Description

The Electrical and Mechanical Modules (Fd) module of the foundation degreeAudience

Only those enrolled via the University on the Applied Engineering ProgrammeDuration:

0 Day(s)Class size:

0

Course Name

Electrical and Mechanical Modules (Fd)Course Description

The Electrical and Mechanical Modules (Fd) module of the foundation degreeAudience

Only those enrolled via the University on the Applied Engineering ProgrammeDuration:

0 Day(s)Class size:

0Competence Name Awarded:

N/ACompetence Awarded:

N/ACourse Code:

FDREPrerequisite Name:

N/APrerequisite Short Code:

N/ASkills Assessment Scheme Regime:

N/ACourse Type:

Course Name

Installation and Maintenance of Rail Mounted Mechanical TreadlesCourse Description

This training course is designed to provide delegates with the knowledge and theory associated with Installation and Maintenance of Rail Mounted Mechanical Treadles. Upon completion of the eLearning you will be required to pass a theory assessment, after which you will then be awarded Installation and Maintenance of Rail Mounted Mechanical Treadles (Sig 41.01) competence at Level 2. To uplift to Level 3, a period of action learning is required.Audience

Persons who are required to team leaders, technicians and operatives within the maintenance organisation. The solution will also be of relevance to signal works testing staff.Duration:

0.25 Day(s)Class size:

Course Name

Installation and Maintenance of Rail Mounted Mechanical TreadlesCourse Description

<p>This training course is designed to provide delegates with the knowledge and theory associated with Installation and Maintenance of Rail Mounted Mechanical Treadles. <br /> <br /> Upon completion of the eLearning you will be required to pass a theory assessment, after which you will then be awarded Installation and Maintenance of Rail Mounted Mechanical Treadles (Sig 41.01) competence at Level 2. <br /> <br /> To uplift to Level 3, a period of action learning is required.</p>Audience

Persons who are required to team leaders, technicians and operatives within the maintenance organisation. The solution will also be of relevance to signal works testing staff.Duration:

0.25 Day(s)Class size:

Competence Name Awarded:

Treadles Core. Undertake corrective and preventative maintenance, replacement and installation of rail mounted mechanical treadlesCompetence Awarded:

Sig 41.01Course Code:

STF 90001.E.bPrerequisite Name:

Treadles CorePrerequisite Short Code:

Sig 41Skills Assessment Scheme Regime:

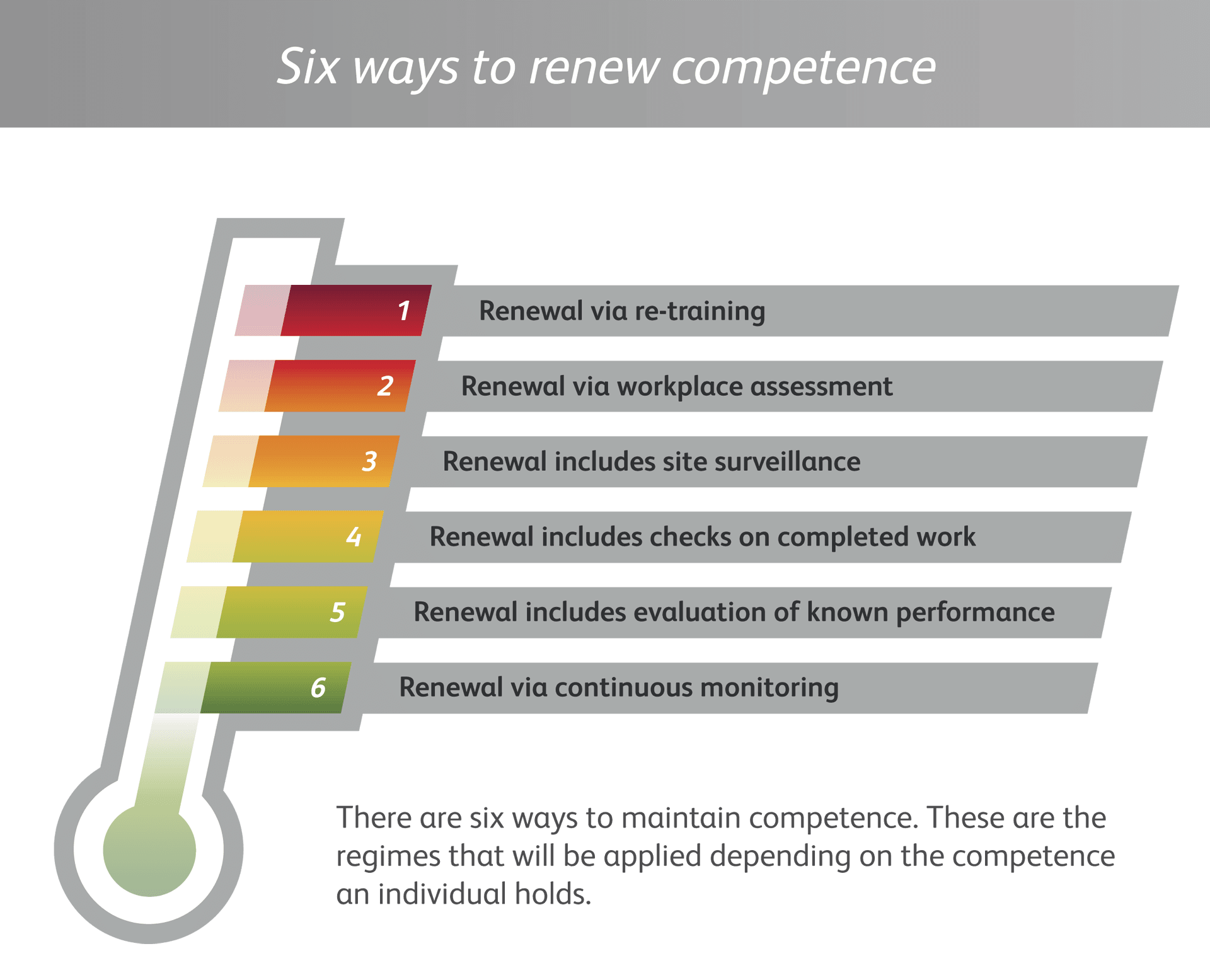

5Course Type:

Course Name

Mechanical & Electrical Interlocking Basic PrinciplesCourse Description

This course introduces you to mechanical and electrical interlocking covered the following areas: • An overview of mechanical interlocking, electrical locking and levers and lever frames • Typical locking functions and mechanical locking tables • Direct and indirect tappet locking, duplex and non-tappet locking, mechanical locking charts and ground frames • Electric locks, circuit controllers and economisers This course consists of four eLearning modules and activities that need to be completed on the Digital TwinAudience

This course introduces you to mechanical and electrical interlocking, and consists of four eLearning modules and digital twin activities.Duration:

5 Hours Day(s)Class size:

9999

Course Name

Mechanical & Electrical Interlocking Basic PrinciplesCourse Description

<p>This course introduces you to mechanical and electrical interlocking covered the following areas:<br /> • An overview of mechanical interlocking, electrical locking and levers and lever frames<br /> • Typical locking functions and mechanical locking tables<br /> • Direct and indirect tappet locking, duplex and non-tappet locking, mechanical locking charts and ground frames<br /> • Electric locks, circuit controllers and economisers</p> <p>This course consists of four eLearning modules and activities that need to be completed on the Digital Twin</p>Audience

This course introduces you to mechanical and electrical interlocking, and consists of four eLearning modules and digital twin activities.Duration:

5 Hours Day(s)Class size:

9999Competence Name Awarded:

Competence Awarded:

Course Code:

STF 90004.EPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

Course Name

Mechanical GatesCourse Description

This training course is designed to provide learners with knowledge of Mechanical Gates and the relevant maintenance procedures, faulting and provide them with the opportunity to understand how this applies to their role and day-to-day work.Audience

The target audience for the solution is front line workers, specifically those who carry out maintenance on mechanical gates.Duration:

0.25 Day(s)Class size:

Course Name

Mechanical GatesCourse Description

<p>This training course is designed to provide learners with knowledge of Mechanical Gates and the relevant maintenance procedures, faulting and provide them with the opportunity to understand how this applies to their role and day-to-day work.</p>Audience

The target audience for the solution is front line workers, specifically those who carry out maintenance on mechanical gates.Duration:

0.25 Day(s)Class size:

Competence Name Awarded:

CCS Lx Mechanical Gates.Competence Awarded:

SIG MAINT LX 01.204Course Code:

STF 90037.EPrerequisite Name:

CCS Level Crossing SystemsPrerequisite Short Code:

SIG MAINT LX 01Skills Assessment Scheme Regime:

Course Type:

Course Name

Mechanical Interlocking FLMFCourse Description

Describe the engineering specifications associated with the type lever frame, lock or circuit controller for which competence is being assessed. Describe how the maintenance adjustment, faulting, repair and testing activity may affect the safe operation of the railway. Understand what terminology and methods are used to identify locking components and describe the position of a lever. Understand the reporting lines and escalation procedures.Audience

This course is designed to develop the delegates understanding of corrective and preventative maintenance techniques that need to be applied to mechanical interlocking systems. Pre-Requisites: Before attending this training a person should have successfully completed Signal Maintenance 2, SMT Core and has at least 3 years workplace experience.Duration:

10 Day(s)Class size:

4

Course Name

Mechanical Interlocking FLMFCourse Description

<p>Describe the engineering specifications associated with the type lever frame, lock or circuit controller for which competence is being assessed. Describe how the maintenance adjustment, faulting, repair and testing activity may affect the safe operation of the railway. Understand what terminology and methods are used to identify locking components and describe the position of a lever. Understand the reporting lines and escalation procedures.</p>Audience

This course is designed to develop the delegates understanding of corrective and preventative maintenance techniques that need to be applied to mechanical interlocking systems. Pre-Requisites: Before attending this training a person should have successfully completed Signal Maintenance 2, SMT Core and has at least 3 years workplace experience.Duration:

10 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Lever Frames and Locks & Circuit Controllers.Competence Awarded:

Sig 16Course Code:

STF 107Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits. Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS. Undertake corrective and preventative maintenance of Signalling Power Supplies. Undertake corrective and preventative maintenance of Signalling Cables. Undertake initial diagnosis of failures to determine the necessary course of action. Undertake initial diagnosis of failures to determine the necessary course of action.Fault Finding Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities. Take and relinquish responsibility for Signalling equipment. Signal Maintenance Testing. Signal Maintenance Testing.Core Skills.Prerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 23.01; Sig 24; Sig 25; SMTH; SMTH.01Skills Assessment Scheme Regime:

4Course Type:

Course Name

Mechanical Signalling InstallationCourse Description

How the installation activity may affect the safe operation of the railway. What procedures need to be followed to ensure operational and personal safety is maintained during the work. How to avoid personal injury during the work. How the mechanical points and signals are designed to function under normal operating conditions. What each of the components parts contributes to the overall operation of the system.Audience

This course is designed to train persons required to install and adjust mechanical points and signals. Pre-requisites: Have successfully completed Signal Maintenance 2 Has at least 2 years workplace experience.Duration:

5 Day(s)Class size:

6

Course Name

Mechanical Signalling InstallationCourse Description

<p>How the installation activity may affect the safe operation of the railway. What procedures need to be followed to ensure operational and personal safety is maintained during the work. How to avoid personal injury during the work. How the mechanical points and signals are designed to function under normal operating conditions. What each of the components parts contributes to the overall operation of the system.</p>Audience

This course is designed to train persons required to install and adjust mechanical points and signals. Pre-requisites: Have successfully completed Signal Maintenance 2 Has at least 2 years workplace experience.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

Install and adjust Mechanical Point Operating Systems. Install and adjust Mechanical Signals.Competence Awarded:

Sig 32; Sig 33Course Code:

STF 106Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits Undertake corrective and preventative maintenance of Track Circuits Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS Undertake corrective and preventative maintenance of Signalling Power Supplies Undertake corrective and preventative maintenance of Signalling Cables Take and relinquish responsibility for Signalling equipment Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities.Prerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 24; Sig 25Skills Assessment Scheme Regime:

5Course Type:

Course Name

Mechanical Signalling MaintenanceCourse Description

This course consists of three parts: 1. Mechanical signals and ancillary equipment including: Mechanical signal fitted on a post, Mechanical ground signal, Including electrical components the associated with the signal and AWS equipment 2. Mechanical operated points.Audience

Have successfully completed Signal Maintenance 1 Has at least 3 months workplace experienceFollowing completion of the training each delegate shall undertake a period of mentored workplace experience to enable the learning to be consolidated through practical workplace experience.Duration:

5 Day(s)Class size:

4

Course Name

Mechanical Signalling MaintenanceCourse Description

<p>This course consists of three parts: 1. Mechanical signals and ancillary equipment including: Mechanical signal fitted on a post, Mechanical ground signal, Including electrical components the associated with the signal and AWS equipment 2. Mechanical operated points.</p>Audience

Have successfully completed Signal Maintenance 1 Has at least 3 months workplace experienceFollowing completion of the training each delegate shall undertake a period of mentored workplace experience to enable the learning to be consolidated through practical workplace experience.Duration:

5 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Mechanical Signals and AWS equipment. CCS Install, Setup and Maintain Point Equipment; Mechanical Points.Competence Awarded:

Sig 08; ; Sig Maint Points 01.001Course Code:

STF 105Prerequisite Name:

Undertake preventative maintenance of Electrical Signals and AWS Undertake preventative maintenance of Signalling Cables Undertake preventative maintenance of Signalling Power Supplies Undertake preventative maintenance of Track Circuits Work safely on Signalling Power SuppliesPrerequisite Short Code:

SEM1 (STF 001 [Sig 01, 02, 03, 04])Skills Assessment Scheme Regime:

3, 5Course Type:

Course Name

SMTH Mechanical Locking Practical AssessmentCourse Description

This is a practical assessment, delivered in York Training Centre. The delegate is required to undertake an assessment related to the renewal of the Mechanical Locking Testing competence.Audience

Staff who will be required to undertake SMTH Mechanical Locking Testing as a regular part of their work place activitiesDuration:

0.5 Day(s)Class size:

1

Course Name

SMTH Mechanical Locking Practical AssessmentCourse Description

<p>This is a practical assessment, delivered in York Training Centre. The delegate is required to undertake an assessment related to the renewal of the Mechanical Locking Testing competence.</p>Audience

Staff who will be required to undertake SMTH Mechanical Locking Testing as a regular part of their work place activitiesDuration:

0.5 Day(s)Class size:

1Competence Name Awarded:

CCS Signal Maintenance Testing Mechanical Frame Locking Core CCS Signal Maintenance Testing Mechanical Frame Locking Core; ComplexCompetence Awarded:

SIG MAINT TEST SMTH.MFL, SIG MAINT TEST SMTH.MFL CMPLXCourse Code:

STF 610Prerequisite Name:

CCS Signal Maintenance Testing Mechanical Frame Locking CorePrerequisite Short Code:

SIG MAINT TEST SMTH.MFLSkills Assessment Scheme Regime:

2Course Type:

Course Name

Electrical and Mechanical Modules (BEng)Course Description

The Electrical and Mechanical Modules (BEng) of the Beng in Railway Engineering at Sheffield Hallam UniversityAudience

Only those enrolled via the University on the Applied Engineering ProgrammeDuration:

0 Day(s)Class size:

0Competence Name Awarded:

N/ACompetence Awarded:

N/ACourse Code:

BENGREPrerequisite Name:

N/APrerequisite Short Code:

N/ASkills Assessment Scheme Regime:

N/ACourse Type:

How to Book

Course Name

Electrical and Mechanical Modules (Fd)Course Description

The Electrical and Mechanical Modules (Fd) module of the foundation degreeAudience

Only those enrolled via the University on the Applied Engineering ProgrammeDuration:

0 Day(s)Class size:

0Competence Name Awarded:

N/ACompetence Awarded:

N/ACourse Code:

FDREPrerequisite Name:

N/APrerequisite Short Code:

N/ASkills Assessment Scheme Regime:

N/ACourse Type:

How to Book

Course Name

Installation and Maintenance of Rail Mounted Mechanical TreadlesCourse Description

<p>This training course is designed to provide delegates with the knowledge and theory associated with Installation and Maintenance of Rail Mounted Mechanical Treadles. <br /> <br /> Upon completion of the eLearning you will be required to pass a theory assessment, after which you will then be awarded Installation and Maintenance of Rail Mounted Mechanical Treadles (Sig 41.01) competence at Level 2. <br /> <br /> To uplift to Level 3, a period of action learning is required.</p>Audience

Persons who are required to team leaders, technicians and operatives within the maintenance organisation. The solution will also be of relevance to signal works testing staff.Duration:

0.25 Day(s)Class size:

Competence Name Awarded:

Treadles Core. Undertake corrective and preventative maintenance, replacement and installation of rail mounted mechanical treadlesCompetence Awarded:

Sig 41.01Course Code:

STF 90001.E.bPrerequisite Name:

Treadles CorePrerequisite Short Code:

Sig 41Skills Assessment Scheme Regime:

5Course Type:

How to Book

Course Name

Mechanical & Electrical Interlocking Basic PrinciplesCourse Description

<p>This course introduces you to mechanical and electrical interlocking covered the following areas:<br /> • An overview of mechanical interlocking, electrical locking and levers and lever frames<br /> • Typical locking functions and mechanical locking tables<br /> • Direct and indirect tappet locking, duplex and non-tappet locking, mechanical locking charts and ground frames<br /> • Electric locks, circuit controllers and economisers</p> <p>This course consists of four eLearning modules and activities that need to be completed on the Digital Twin</p>Audience

This course introduces you to mechanical and electrical interlocking, and consists of four eLearning modules and digital twin activities.Duration:

5 Hours Day(s)Class size:

9999Competence Name Awarded:

Competence Awarded:

Course Code:

STF 90004.EPrerequisite Name:

Prerequisite Short Code:

Skills Assessment Scheme Regime:

Course Type:

How to Book

Course Name

Mechanical GatesCourse Description

<p>This training course is designed to provide learners with knowledge of Mechanical Gates and the relevant maintenance procedures, faulting and provide them with the opportunity to understand how this applies to their role and day-to-day work.</p>Audience

The target audience for the solution is front line workers, specifically those who carry out maintenance on mechanical gates.Duration:

0.25 Day(s)Class size:

Competence Name Awarded:

CCS Lx Mechanical Gates.Competence Awarded:

SIG MAINT LX 01.204Course Code:

STF 90037.EPrerequisite Name:

CCS Level Crossing SystemsPrerequisite Short Code:

SIG MAINT LX 01Skills Assessment Scheme Regime:

Course Type:

How to Book

Course Name

Mechanical Interlocking FLMFCourse Description

<p>Describe the engineering specifications associated with the type lever frame, lock or circuit controller for which competence is being assessed. Describe how the maintenance adjustment, faulting, repair and testing activity may affect the safe operation of the railway. Understand what terminology and methods are used to identify locking components and describe the position of a lever. Understand the reporting lines and escalation procedures.</p>Audience

This course is designed to develop the delegates understanding of corrective and preventative maintenance techniques that need to be applied to mechanical interlocking systems. Pre-Requisites: Before attending this training a person should have successfully completed Signal Maintenance 2, SMT Core and has at least 3 years workplace experience.Duration:

10 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Lever Frames and Locks & Circuit Controllers.Competence Awarded:

Sig 16Course Code:

STF 107Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits. Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS. Undertake corrective and preventative maintenance of Signalling Power Supplies. Undertake corrective and preventative maintenance of Signalling Cables. Undertake initial diagnosis of failures to determine the necessary course of action. Undertake initial diagnosis of failures to determine the necessary course of action.Fault Finding Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities. Take and relinquish responsibility for Signalling equipment. Signal Maintenance Testing. Signal Maintenance Testing.Core Skills.Prerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 23.01; Sig 24; Sig 25; SMTH; SMTH.01Skills Assessment Scheme Regime:

4Course Type:

How to Book

Course Name

Mechanical Signalling InstallationCourse Description

<p>How the installation activity may affect the safe operation of the railway. What procedures need to be followed to ensure operational and personal safety is maintained during the work. How to avoid personal injury during the work. How the mechanical points and signals are designed to function under normal operating conditions. What each of the components parts contributes to the overall operation of the system.</p>Audience

This course is designed to train persons required to install and adjust mechanical points and signals. Pre-requisites: Have successfully completed Signal Maintenance 2 Has at least 2 years workplace experience.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

Install and adjust Mechanical Point Operating Systems. Install and adjust Mechanical Signals.Competence Awarded:

Sig 32; Sig 33Course Code:

STF 106Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits Undertake corrective and preventative maintenance of Track Circuits Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS Undertake corrective and preventative maintenance of Signalling Power Supplies Undertake corrective and preventative maintenance of Signalling Cables Take and relinquish responsibility for Signalling equipment Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities.Prerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 24; Sig 25Skills Assessment Scheme Regime:

5Course Type:

How to Book

Course Name

Mechanical Signalling MaintenanceCourse Description

<p>This course consists of three parts: 1. Mechanical signals and ancillary equipment including: Mechanical signal fitted on a post, Mechanical ground signal, Including electrical components the associated with the signal and AWS equipment 2. Mechanical operated points.</p>Audience

Have successfully completed Signal Maintenance 1 Has at least 3 months workplace experienceFollowing completion of the training each delegate shall undertake a period of mentored workplace experience to enable the learning to be consolidated through practical workplace experience.Duration:

5 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Mechanical Signals and AWS equipment. CCS Install, Setup and Maintain Point Equipment; Mechanical Points.Competence Awarded:

Sig 08; ; Sig Maint Points 01.001Course Code:

STF 105Prerequisite Name:

Undertake preventative maintenance of Electrical Signals and AWS Undertake preventative maintenance of Signalling Cables Undertake preventative maintenance of Signalling Power Supplies Undertake preventative maintenance of Track Circuits Work safely on Signalling Power SuppliesPrerequisite Short Code:

SEM1 (STF 001 [Sig 01, 02, 03, 04])Skills Assessment Scheme Regime:

3, 5Course Type:

How to Book

Course Name

SMTH Mechanical Locking Practical AssessmentCourse Description

<p>This is a practical assessment, delivered in York Training Centre. The delegate is required to undertake an assessment related to the renewal of the Mechanical Locking Testing competence.</p>Audience

Staff who will be required to undertake SMTH Mechanical Locking Testing as a regular part of their work place activitiesDuration:

0.5 Day(s)Class size:

1Competence Name Awarded:

CCS Signal Maintenance Testing Mechanical Frame Locking Core CCS Signal Maintenance Testing Mechanical Frame Locking Core; ComplexCompetence Awarded:

SIG MAINT TEST SMTH.MFL, SIG MAINT TEST SMTH.MFL CMPLXCourse Code:

STF 610Prerequisite Name:

CCS Signal Maintenance Testing Mechanical Frame Locking CorePrerequisite Short Code:

SIG MAINT TEST SMTH.MFLSkills Assessment Scheme Regime:

2Course Type:

How to Book